coal grinding processes

Grinding process within vertical roller mills: experiment and ...

2009年1月1日 Four grinding circuits are used with different materials: vertical mills (Loesche) for coal and cement feed; vertical roller mills for cement clinkers; and ball mills

Read More

Generation of low ash fine clean coal powder by autogenous grinding ...

2019年1月15日 Coal autogenous grinding process explored for improved liberation characteristics. •. This process able to generate low ash clean coal (16.5%) directly by

Read More

Interrelationship of coal grinding properties and coal

1998年8月1日 The Hardgrove grindability index (HGI) is a widely used coal-quality parameter with applications in coal mining, beneficiation, and utilization. An

Read More

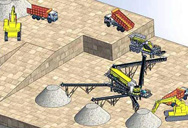

Design of coal preparation plants: problems and

2024年3月12日 During the process of coal transportation from the mine (open cast) to the CPP the coal grinding occurs. Its composition varies in both size and quality of individual

Read More

Coal grinding technology: a manual for process engineers.

Then the coal undergoes pulverization which reduces the top size to 1/8'' and/or grinding which reduces the top size to 1 mm or less. This handbook examines the intermediate

Read More

(PDF) Modeling of the process of coal grinding - ResearchGate

2013年4月1日 The purpose of the study was to investigate the change of the gas permeability of different types of coal as a result of phenomena occuring in the processes

Read More

Production of Ultra-Clean Coal by the Combined

2022年12月19日 The effects of grinding time on the particle size composition, mineral dissociation, surface properties and flotation results of coal samples were studied. The grinding test results show that with the

Read More

Influence of Grinding Methodology and Particle

2023年6月1日 This study compares the influence of the method of grinding, mixing coal and biomass on the processes of spraying mixtures with a change in the pressure of the atomizing air.

Read More

Design of coal preparation plants: problems and

2024年3月12日 formed many studies devoted to simulation of coal grinding processes to obtain reliable data for CPP design. We offer methods of determination of coal size degradation during delivery from mine, open pit stock dumps to the preparation plant. [4,5] The root of the method of determination of coal size degradation during delivery from

Read More

The effect of the grinding process on pore structures,

2019年1月1日 Effect of the grinding process on pore structures. As described in Table 1, the content of moisture reduces with the decrease of particle size. Due to the extrusion deformation of steel ball during the milling process, macromolecular structure of pulverized coal is fractured.

Read More

Modeling and Industrial Development of Grinding Processes

2022年9月12日 where R w is the wrapper’s working radius; b is the distance between the rollers (the width of the output slot); r p is the conventional radius of the piece; and γ fr is the frictional angle of the material at the wrapper surface. We know that γ fr = tan μ, where μ is the frictional coefficient of the material being crushed at the wrapper.. In the present

Read More

What is Grinding Process How It Works - Different Types

2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision. It is widely used in the machinery manufacturing industry. The heat-treated and quenched carbon tool steel and carburized and quenched steel parts often have a large number of regularly arranged grinding cracks on the surface that is basically

Read More

Indirect Firing Coal Grinding Systems: Enhancing Efficiency

2024年7月25日 In coal combustion, the efficiency and safety of the process are paramount. Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing. This article explores the components, advantages, and operational considerations of indirect firing c

Read More

Ensuring Safety in Coal Grinding Operations Coal Mill Safety ...

2024年7月25日 Coal grinding is a critical process in the production of energy and industrial products like cement. It comes with inherent risks. Ensuring the safety of workers and equipment in coal grinding operations is paramount. This article outlines key safety measures and best practices to mitigate the hazards associated with coal grinding.

Read More

Ensuring Safety in Coal Mills – Best Practices and Precautions Coal ...

2024年9月28日 Coal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed. These mills, used to grind coal into a fine powder for combustion, present potential hazards such as fire, explosion, and mechanical failures. This article outlines best practices and precautions to

Read More

Production of Ultra-Clean Coal by the Combined Method of Grinding

2022年12月19日 The preparation and application of ultra-clean coal is one of the important aspects of clean energy technology. However, the preparation of ultra-clean coal is mainly chemical methods, which are low in efficiency, high in energy consumption and expensive. It is urgent to find an effective method to prepare ultra-clean coal. In this paper, the

Read More

An investigation of performance characteristics and

2020年8月12日 Tontu [14] investigated the relationships between the current, coal feed, grinding pressure, and primary air and outlet temperatures of coal mills, and proved that a high correlation exists ...

Read More

Grinding in Ball Mills: Modeling and Process Control

grinding process and analyze several control strategies applied in the design of a control structure and the implementation of an appropriate process control method. II. Modeling of the process II.1. Basic fragmentation mechanisms The main idea in modeling all comminution processes, including the grinding

Read More

Influence of the Grinding Media Applying in the Soft Coal

2020年9月16日 In this study, experiments were conducted to evaluate the effects of the composition of a grinding medium on the reactivity of mixed carbon materials. Orange peel (OP) was mechanically ground into powder with soft coal (SC) under different media. The potential value of the carbonaceous reducing agent in industrial silicon production was

Read More

Mechanistic study of the effects of ultrafine grinding on the

2024年9月1日 Changes in the surface wettabilities of the coal samples during fine grinding were characterized using a DSA100 (Kruss-Scientific, Germany) contact-angle measuring instrument. ... Images were obtained 2 s after the initiation of contact between the droplet and thin slice of the coal sample. This process was performed three times to achieve ...

Read More

Beneficiation of ponded coal ash through chemi-mechanical grinding

2021年9月1日 Ponded coal ash are ideal waste for chemi-mechanical beneficiation. ... The results show that both grinding processes increased the quantity of both over and undersized particles, making the PSD less uniform. The increase in oversized particles in both milling processes was likely caused by a combination of agglomerating particles

Read More

Optimization of grinding process for hard and brittle

2024年3月1日 To simplify the analysis of crack propagation during the grinding process, the extended finite element method (XFEM) in Abaqus was used to establish the indentation method prefabricated crack model to study the influence of existing damage on crack propagation at the same grit penetration depth, as shown in Fig. 1 (a). The XFEM

Read More

(PDF) Modeling of the process of coal grinding - ResearchGate

2013年4月1日 The use of coal in the steel industry, similarly as in the whole national economy, is often preceded by its pre-treatment. Coal is mined in the form of big solids, but, being in such a form, it ...

Read More

Study on modes of occurrence and selective leaching of lithium in coal ...

2024年2月15日 Study on modes of occurrence and selective leaching of lithium in coal gangue via grinding-thermal activation. Author links open overlay panel Hangchao Chen 1, Lei Zhang 1, Jinhe Pan, Xin He, ... To enhance the efficiency of selective extraction of Li, a combined process of grinding-thermal activation was proposed, and the influence of

Read More

Ball Grinding Process - SpringerLink

2023年7月27日 Ball grinding process is a grinding method of crushing ore with ball-shaped grinding medium in the grinding mill. In the ball grinding process, because the steel ball has 360° free rotation, it is suitable for falling motion and throwing motion. ... The former is widely used in coal-fired power plants and cement industry, and the latter is ...

Read More

Improving the efficiency of the coal grinding process in ball

2022年2月24日 The proposed methodology allows adjustment of the operating parameters of the grinding process to achieve the lowest energy consumption. The power consumption for the preparation can be reduced up ...

Read More

MODELING OF THE PROCESS OF COAL GRINDING - Srce

Key words: coal, modeling of grinding process, grain size distribution, Maxwell-Boltzmann law, numerical predic-tion INTRODUCTION The development of humankind is inseparably con-nected with the use of energy, whose generation in-volves the use of energy raw-materials. Currently, fossil fuels, such as hard coal, brown coal, petroleum and nat-

Read More

A critical review on the mechanisms of chemical additives

2020年7月1日 Enustun et al. [16] investigated the effect of Aquard ™, (an ammonium chloride-based GA) on the grinding of coal. The GA resulted in selective grinding of the inorganic matter (pyrite), which presents an opportunity of simplifying coal washing to a mere separation by size process [16]. This is all attributed to the preferential grinding ...

Read More